What Is the Minimum Order Quantity for Custom Tech Gifts in UAE?

Expert Quick Answer

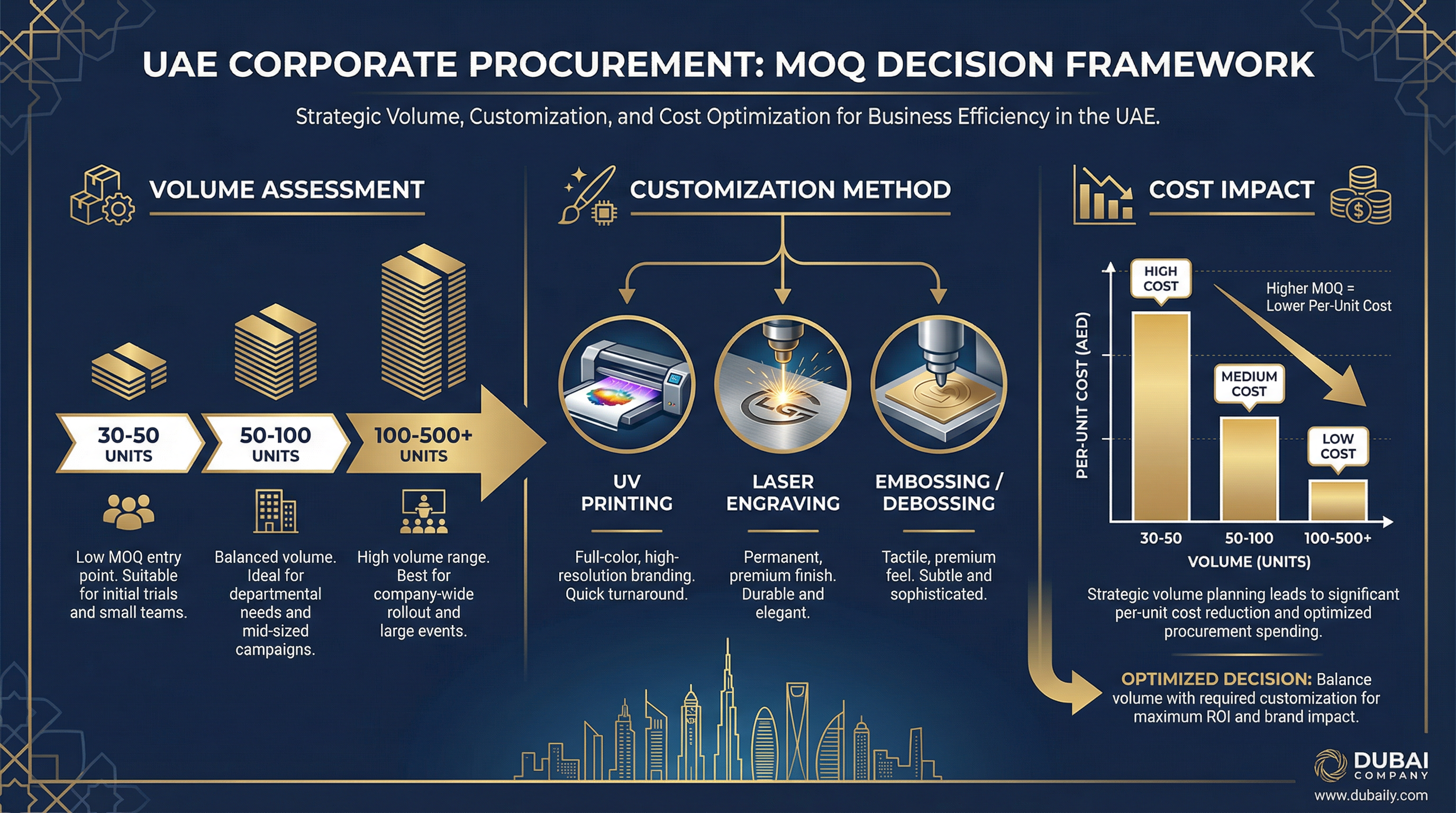

Minimum order quantities for custom tech gifts in the UAE typically range from 30 to 100 units, depending on the product category, customization method, and supplier capabilities. Power banks and wireless chargers generally require 50-100 units for UV printing or laser engraving, while simpler items like USB drives may start at 30 units. The MOQ is not arbitrary—it reflects production setup costs, material procurement thresholds, and the economics of customization processes. UAE-based corporate buyers should expect higher MOQs for complex branding methods (embossing, LED logos) and lower thresholds for digital printing techniques.

Why This Question Matters for UAE Enterprises

Corporate procurement teams in the UAE face distinct challenges when sourcing custom tech gifts. Unlike consumer purchases, B2B orders must balance budget constraints, brand consistency requirements, and tight event timelines. The minimum order quantity directly impacts three critical business factors: unit cost economics, inventory risk, and supplier selection criteria.

When a company commits to an MOQ, it locks in capital that could otherwise be deployed elsewhere. For employee recognition programs running quarterly, ordering 200 units when only 80 are needed creates unnecessary cash flow pressure. Conversely, underestimating demand and placing multiple small orders inflates per-unit costs due to repeated setup fees.

UAE enterprises operating across multiple Emirates—or coordinating regional gifting programs spanning GCC markets—must also consider warehousing implications. A 500-unit MOQ for premium power banks may seem reasonable until factoring in Dubai's storage costs and the risk of obsolescence if product specifications change within six months.

The MOQ question becomes even more consequential during pilot programs. HR departments testing new onboarding kits or marketing teams trialing conference giveaways need flexibility to validate effectiveness before scaling. Suppliers with rigid 500-unit minimums effectively price out experimentation, forcing companies to either commit prematurely or abandon customization altogether.

Common Practices Among UAE Enterprises

Testing with lower-tier products before committing to premium lines. Companies often place initial orders for mid-range wireless chargers or standard power banks to assess supplier reliability, print quality, and delivery timelines. Once confidence is established, they upgrade to executive-tier products with higher MOQs and more complex customization.

Consolidating multiple departments into single orders. Rather than HR, marketing, and sales each placing separate 50-unit orders, procurement teams aggregate demand to meet 200-unit thresholds. This approach unlocks better pricing and ensures brand consistency across all corporate gifting initiatives.

Negotiating phased delivery against total commitment. Enterprises with predictable annual demand—such as banks distributing gifts during Ramadan and year-end—commit to 500 units upfront but request delivery in two 250-unit batches. This reduces warehousing burden while still qualifying for volume pricing.

Partnering with suppliers offering MOQ flexibility for repeat clients. After establishing a track record with 2-3 successful orders, some UAE companies negotiate permanent MOQ reductions. A supplier initially requiring 100 units may agree to 50-unit minimums for clients demonstrating consistent quarterly demand.

Accepting mixed SKU orders to meet aggregate thresholds. Instead of ordering 100 units of a single power bank model, companies combine 50 units of 10000mAh models with 50 units of 5000mAh variants. This strategy works when suppliers calculate MOQ based on total production volume rather than per-SKU requirements.

Key Factors Influencing MOQ Requirements

Customization method complexity. UV printing and laser engraving involve setup costs that suppliers amortize across order volume. A UV printer requires color calibration, test prints, and material waste before production begins. Suppliers cannot justify this overhead for 20 units, but 100 units make the economics viable. Conversely, digital printing methods with minimal setup allow lower MOQs—sometimes as few as 25 units—because per-unit variable costs dominate fixed setup expenses.

Product category and component sourcing. Power banks with specific battery capacities require suppliers to procure cells in manufacturer-defined lot sizes. If a battery supplier only sells 27000mAh cells in 100-unit increments, the custom power bank MOQ cannot fall below that threshold. Similarly, Bluetooth speakers using proprietary drivers may face component MOQs that cascade into finished product minimums.

Branding area size and logo complexity. A simple single-color logo on a flat surface (USB drive cap, wireless charger top) requires less setup than a full-wrap print on a cylindrical power bank. Multi-color gradients, metallic finishes, or logos spanning curved surfaces increase setup time and material waste, pushing MOQs higher to maintain supplier profitability.

Packaging customization requirements. Standard bulk packaging (plain white boxes) rarely affects MOQ. However, custom gift boxes with printed interiors, foam inserts, or branded sleeves introduce separate MOQ thresholds. A supplier may accept 50 units for product customization but require 200 units if custom packaging is included, as box manufacturers impose their own minimums.

Supplier business model and target client segment. Suppliers focused on large enterprises (500+ employee companies) structure operations around high-volume efficiency, resulting in 200-500 unit MOQs. Suppliers targeting SMEs or agencies invest in flexible production systems that accommodate 30-50 unit orders at slightly higher per-unit costs. UAE buyers must align supplier selection with their typical order volumes.

Practical Recommendations by Enterprise Scale

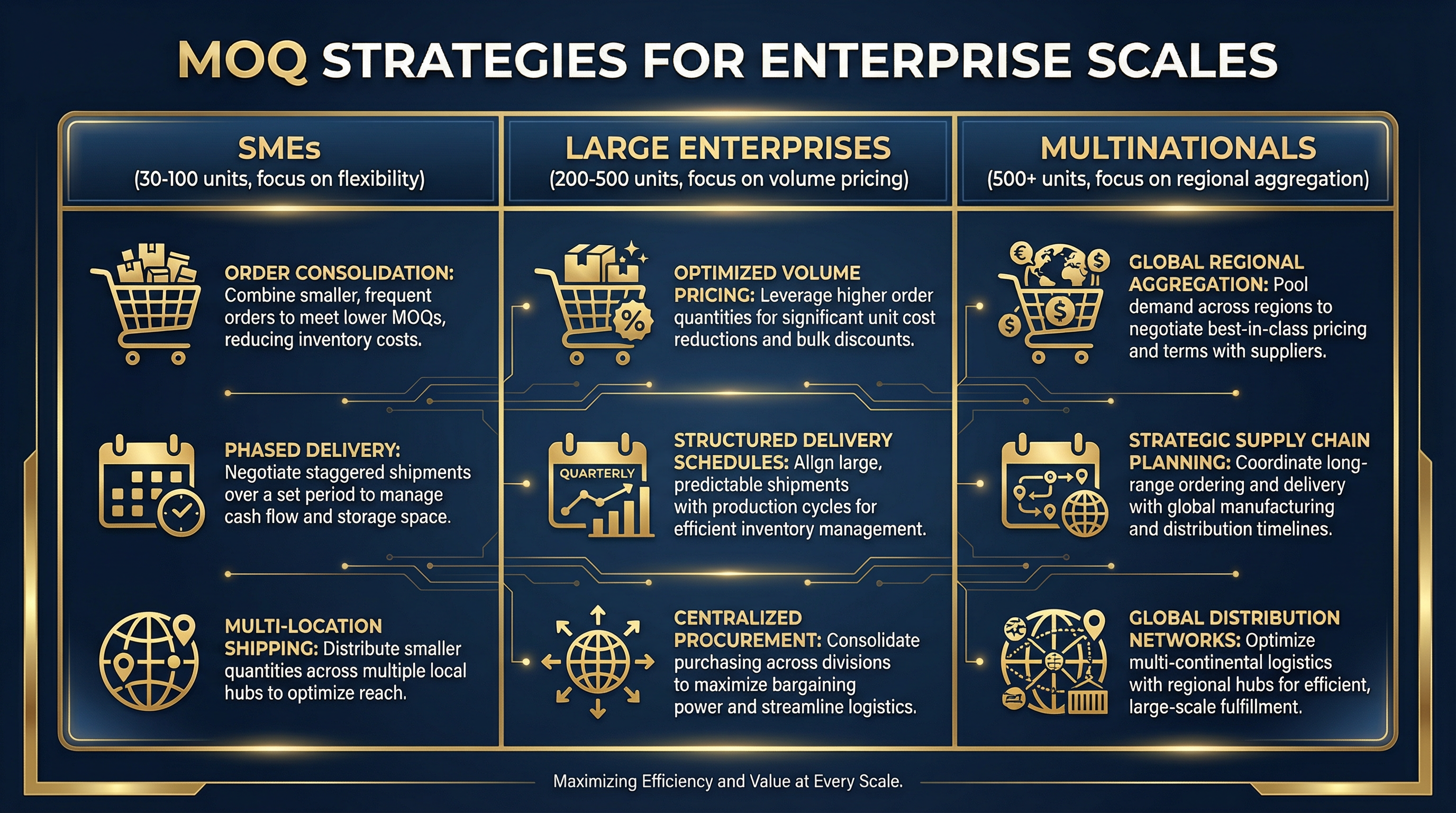

Small and Medium Enterprises (SMEs). Focus on suppliers explicitly serving the 30-100 unit segment. Avoid attempting to negotiate down a large-volume supplier's 500-unit MOQ—their cost structure cannot support it profitably, and quality or service will likely suffer. Instead, prioritize suppliers offering mixed SKU flexibility, allowing you to combine different products (power banks + USB drives) to meet aggregate minimums. When launching new gifting programs, start with digital printing methods rather than laser engraving to access lower MOQs, then upgrade customization techniques once demand is validated.

Large Enterprises (200-1000 employees). Leverage predictable annual demand to negotiate tiered pricing structures. Commit to 500 units annually but structure delivery across quarterly batches aligned with recognition events, onboarding cycles, or seasonal campaigns. This approach secures volume pricing while avoiding excess inventory. Establish relationships with 2-3 suppliers in different MOQ brackets—one for high-volume standard items (employee gifts) and another for low-volume premium products (executive VIP gifts). Avoid single-source dependency, as it limits flexibility when urgent small-batch needs arise.

Multinational Companies and Regional Headquarters. Centralize procurement across GCC operations to aggregate demand from UAE, Saudi Arabia, Qatar, and other markets. A 100-unit order from Dubai and 75 units from Riyadh become a combined 175-unit order qualifying for better pricing and lower per-market MOQs. However, account for import duties, customs clearance timelines, and country-specific compliance requirements (battery capacity restrictions vary by jurisdiction). Consider appointing a regional procurement lead to coordinate orders rather than allowing each country office to source independently.

UAE Market Dynamics vs. Other Regions

UAE corporate procurement operates within a distinct business culture that shapes MOQ expectations differently than Western or Asian markets. The prevalence of free zones—where companies enjoy streamlined import processes and tax advantages—means many UAE enterprises source custom tech gifts through Hong Kong or Shenzhen-based suppliers. These suppliers typically impose 500-1000 unit MOQs optimized for container shipping economics, which can misalign with UAE companies needing 100-200 units for localized events.

Additionally, the UAE's Friday-Saturday weekend and Ramadan observance create timeline compression that affects MOQ flexibility. Suppliers accustomed to Western Monday-Friday schedules may not accommodate requests to expedite 50-unit orders when UAE clients need delivery before a Thursday event. This cultural misalignment often forces UAE buyers to accept higher MOQs from suppliers offering Ramadan-aware production scheduling, even if per-unit costs are slightly elevated.

Frequently Asked Questions in Corporate Practice

Can MOQs be negotiated lower if we commit to repeat orders?

Yes, but only after establishing a track record. Suppliers view first-time buyers as higher risk due to potential artwork revisions, payment delays, or order cancellations. After completing 2-3 orders on time with minimal revisions, buyers gain leverage to negotiate permanent MOQ reductions of 20-30%. However, this requires demonstrating consistent quarterly or bi-annual demand—sporadic annual orders rarely qualify for MOQ flexibility.

Do all products in an order need the same logo, or can we mix designs?

Most suppliers calculate MOQ per unique design rather than per product. If you order 100 power banks but want 50 units with Logo A and 50 units with Logo B, the supplier treats this as two separate 50-unit orders. Each design requires independent setup, so you may not meet the 100-unit MOQ threshold. To avoid this, consolidate orders under a single logo design, or confirm upfront whether the supplier calculates MOQ per SKU or per design.

What happens if we order exactly the MOQ and discover defects?

Reputable suppliers include a 2-5% defect allowance in MOQ calculations and will replace faulty units without requiring a new minimum order. However, if defects exceed this threshold—indicating a systemic production issue—suppliers typically offer three options: full replacement (if they accept responsibility), partial refund, or a discount on the next order. Always clarify defect policies before committing, as some suppliers exclude battery-related failures from warranty coverage.

When Companies Should Evaluate Execution Feasibility

Once enterprises have clarified their volume requirements, budget parameters, and customization preferences, the next logical step involves assessing whether their project aligns with supplier capabilities and realistic production timelines. This evaluation process extends beyond MOQ confirmation into artwork approval workflows, material selection, compliance verification, and delivery coordination.

Companies that have determined their order volume falls within typical MOQ ranges—and have secured internal stakeholder alignment on design specifications—often benefit from reviewing structured guidance on how corporate customization projects move from concept to delivery. This includes understanding proof sample processes, specification lock protocols, and UAE-specific logistics considerations that affect feasibility.

For enterprises ready to move beyond MOQ questions and into execution planning, we have compiled a detailed overview of how custom tech gift projects are structured for UAE corporate buyers. This resource addresses the operational decisions that follow MOQ confirmation, helping procurement teams anticipate process requirements and avoid common execution pitfalls.

More Articles

Why Your Finalized Customization Decision Still Requires Five Days Before UAE Corporate Tech Gift Production Can Begin

Why Your Minor Logo Adjustment Request Requires Five More Days Even Though Production Hasn't Started for UAE Corporate Tech Gifts

Procurement teams believe they can request minor specification revisions anytime before production starts, but factories require a freeze window days before line setup where no changes are accepted.

Why Your '100% Complete' Customization Spec Still Requires Ten Days of Parameter Definition for UAE Corporate Tech Gifts

Procurement teams submit specifications with all template fields filled and expect immediate production, but factories require manufacturing parameters that don't exist in the template.